Why Should You Not Let Capacitors Touch Drone Frame

Introduction

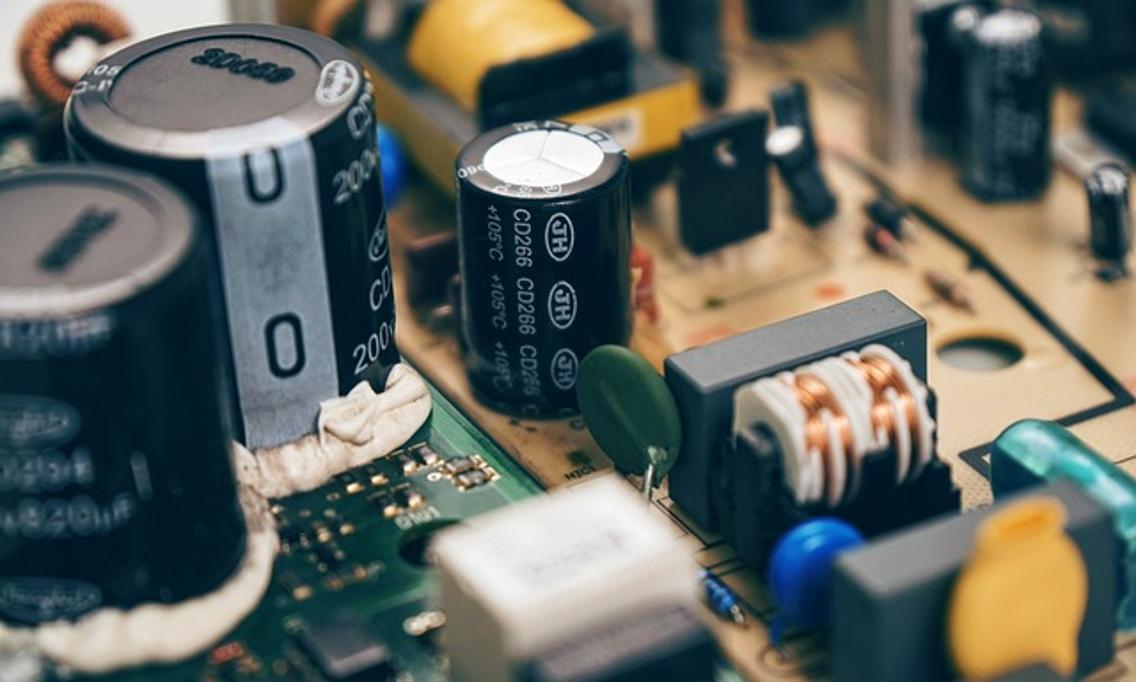

Capacitors, although small, play a significant role in ensuring the smooth operation of your drone. However, improper handling and placement can lead to severe issues. One critical practice is to avoid letting capacitors touch the drone frame. This might seem insignificant, but ignoring this precaution can result in detrimental impacts on your drone's performance and longevity.

Understanding Capacitors and Their Functionality

Capacitors store and release electrical energy, helping stabilize the power supply to various components in your drone. They act as reservoirs, absorbing excess charge and releasing it when needed to maintain a consistent voltage level. This function is essential in drones where fluctuating power can lead to erratic behavior and instability.

Capacitors also help in filtering out noise from the power supply, ensuring that sensitive electronics receive clean and stable power. Without appropriate capacitors, your drone could experience glitches, reduced performance, and even catastrophic failures.

Potential Risks of Capacitors Touching the Drone Frame

Allowing capacitors to touch the drone frame can pose several risks, which can ultimately affect the overall performance and safety of your drone.

Electrical Short Circuits

When a capacitor touches the drone frame, it can create a direct electrical path to the ground, leading to a short circuit. This short circuit can drain the battery quickly, damage electronic components, and potentially cause a fire.

Electromagnetic Interference

Capacitors in direct contact with the drone frame can act as antennas, picking up and radiating electromagnetic interference (EMI). This interference can disrupt the communication between the drone and its controller, leading to loss of control or erratic movements.

Component Damage and Failures

Capacitors touching the frame can also lead to physical damage due to vibrations and movement during flight. Over time, this can weaken the capacitors' connections, causing intermittent failures or complete malfunction of the power systems. The capacitor's casing could also degrade, leaking electrolyte and damaging other components.

Best Practices for Safe Capacitor Placement

To avoid the risks mentioned above, it's crucial to follow best practices for placing and securing capacitors within your drone.

Insulation Techniques

Ensure that capacitors are properly insulated to prevent any direct contact with the drone frame. Use heat shrink tubing or electrical tape around the capacitors to create a barrier. Silicon or rubber sleeves can also provide effective insulation while absorbing vibrations.

Secure Mounting Options

Mount capacitors firmly using adhesives, zip ties, or dedicated capacitor mounts. This ensures that they remain in place even during high-vibration flight conditions. Placing capacitors away from high-stress areas of the frame can also minimize the risk of damage.

Regular Maintenance and Checks

Perform regular maintenance checks to ensure that capacitors are securely in place and free from damage. Inspect the insulation for wear and tear and replace it if necessary. Checking the capacitor connections and their integrity can help prevent unexpected failures during flight.

Real-World Examples and Case Studies

In practice, several drone enthusiasts and professionals have experienced issues due to improper capacitor placement. For instance, a drone racer reported a crash caused by an unexpected power loss. Upon inspection, it was found that a capacitor had come into contact with the frame, leading to a short circuit.

Similarly, in another case, a professional drone used for aerial photography showed erratic behavior and signal loss. Investigation revealed that capacitors were poorly secured and intermittently touched the frame, causing EMI and power fluctuations.

Conclusion

Proper capacitor placement and insulation are critical to ensuring the safe and efficient operation of your drone. By understanding the risks and implementing best practices, you can prevent potential issues and enjoy a seamless flying experience.

Frequently Asked Questions

What materials are best for insulating capacitors in drones?

Heat shrink tubing, electrical tape, and silicon or rubber sleeves are excellent materials for insulating capacitors, providing both electrical isolation and vibration damping.

How often should I check the capacitor placement in my drone?

It's recommended to inspect the capacitor placement before every flight, especially after crashes or rough handling, to ensure they remain securely in place and properly insulated.

Are there any specific industry standards for capacitor placement in drones?

While there are no universal standards, it's best to follow the manufacturer's guidelines and established best practices to ensure capacitors are securely mounted and insulated within your drone.